Fabricating Triumph pinion puller

January 10, 2024

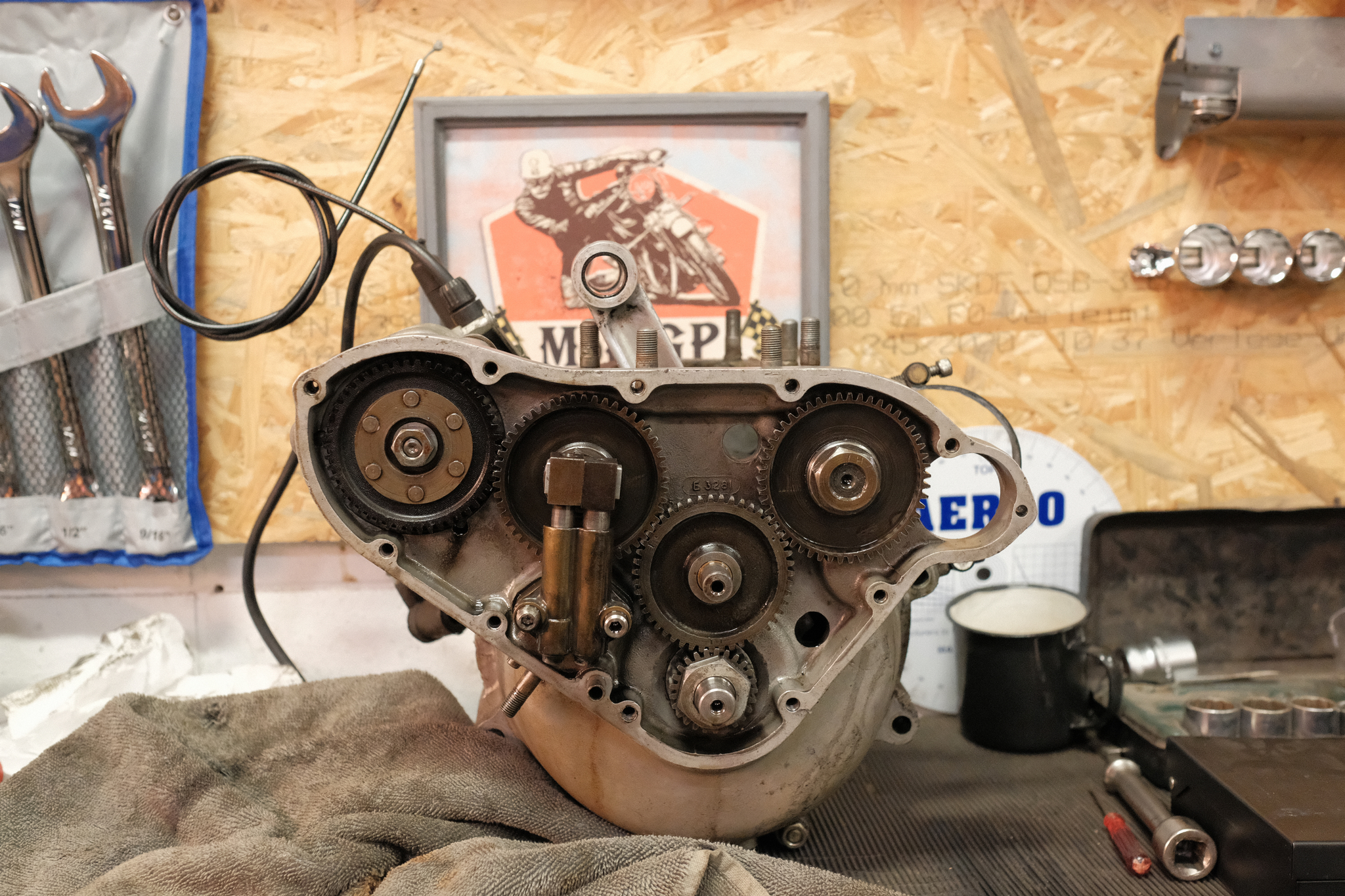

As part of renovating the engine for my 1959 Triumph Bonneville T120 I need to get to the sludge trap in the crankshaft. This means splitting the engine casings and removing the crankshaft. One of the hurdles in this operation is pulling the pinion gear from the crankshaft of the pre unit engine. It is possible to buy the correct tool for the job. I intended to do so. But my local Triumph shop did not have the correct tool in stock, so I decided to try and fabricate one, instead of waiting for one to be shipped the UK or US.

Although the Triumph shop did not sell the tool they let me have a look at the one they used in the shop to use as inspiration.

The correct puller has three arms that go behind the pinion gear and then a threaded conical sleeve that tightens them around the gear so they will not slip. The same way a drill head clamps down on a drill only with taps that go behind the gear to pull it out. Then it works like a normal puller with a bolt that pushed on the crankshaft and hence pulls out the gear.

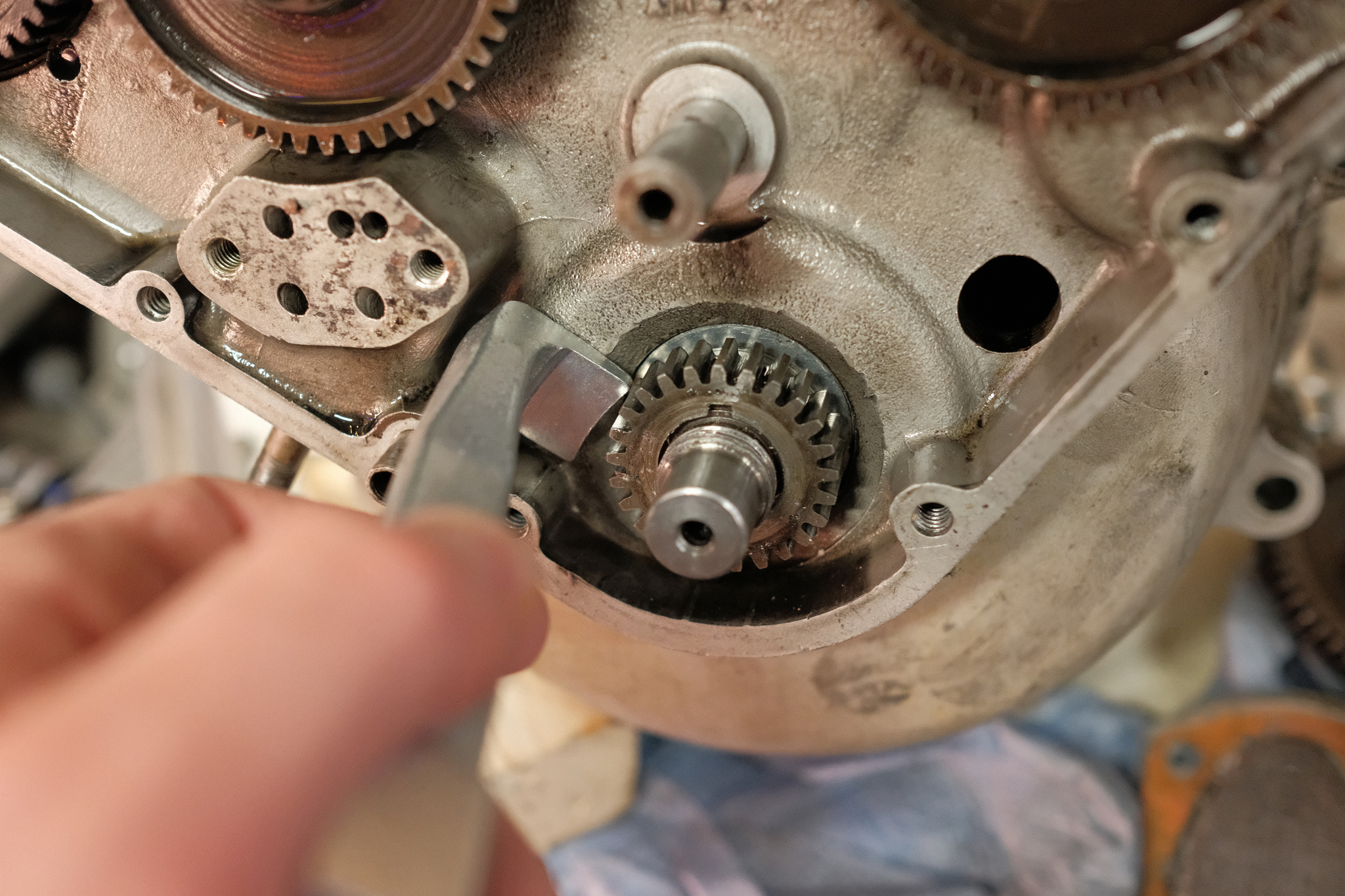

There are primarily two reasons why a “normal” puller will not work. One is that the pinion wheel sits “down” in a sloped recess, which means that a normal puller with 90 degree arms cannot get behind the gear. Secondly the space behind the gear is very limited, so the arms has to be very shallow to get behind it.

With the memory of the correct puller still fresh in mind I went to look for a puller I could modify. First I looked at three-arm pullers but I reckoned that it would be more complicated to keep the arms in around the gear - a big hose clamp could of course work - but the way it pulled the arms seems like ti would be hard to keep the small lip I had to created from slipping out of the gear.

Finally I settled on a two arm puller because it could pull directly away from the gear and with a little help from a vice grip then I thought it was possible to keep the arms from slipping.

When I got back to the garage I could start modifying it to fit behind the pinion gear. But first an image to show how far off it is from the start.

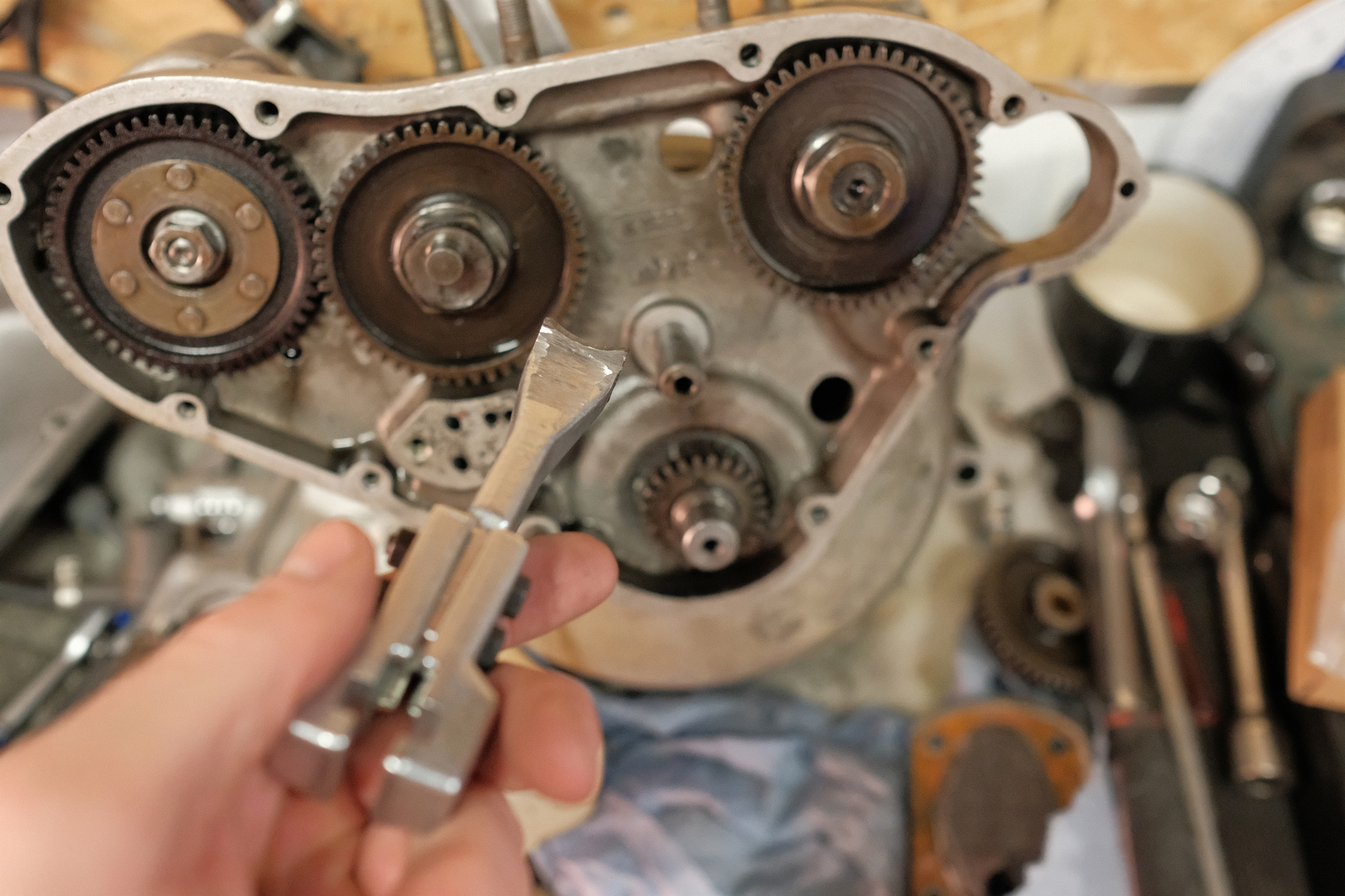

After a lot of grinding and back and forth seeing where it needed additional grinding I ended up with this.

Which fits and can get behind the pinion gear.

To show much I had to remove from the original arm look at the comparison here.

Then all I had to do was grind the other arm down to match the one I already created.

And finally the end result.

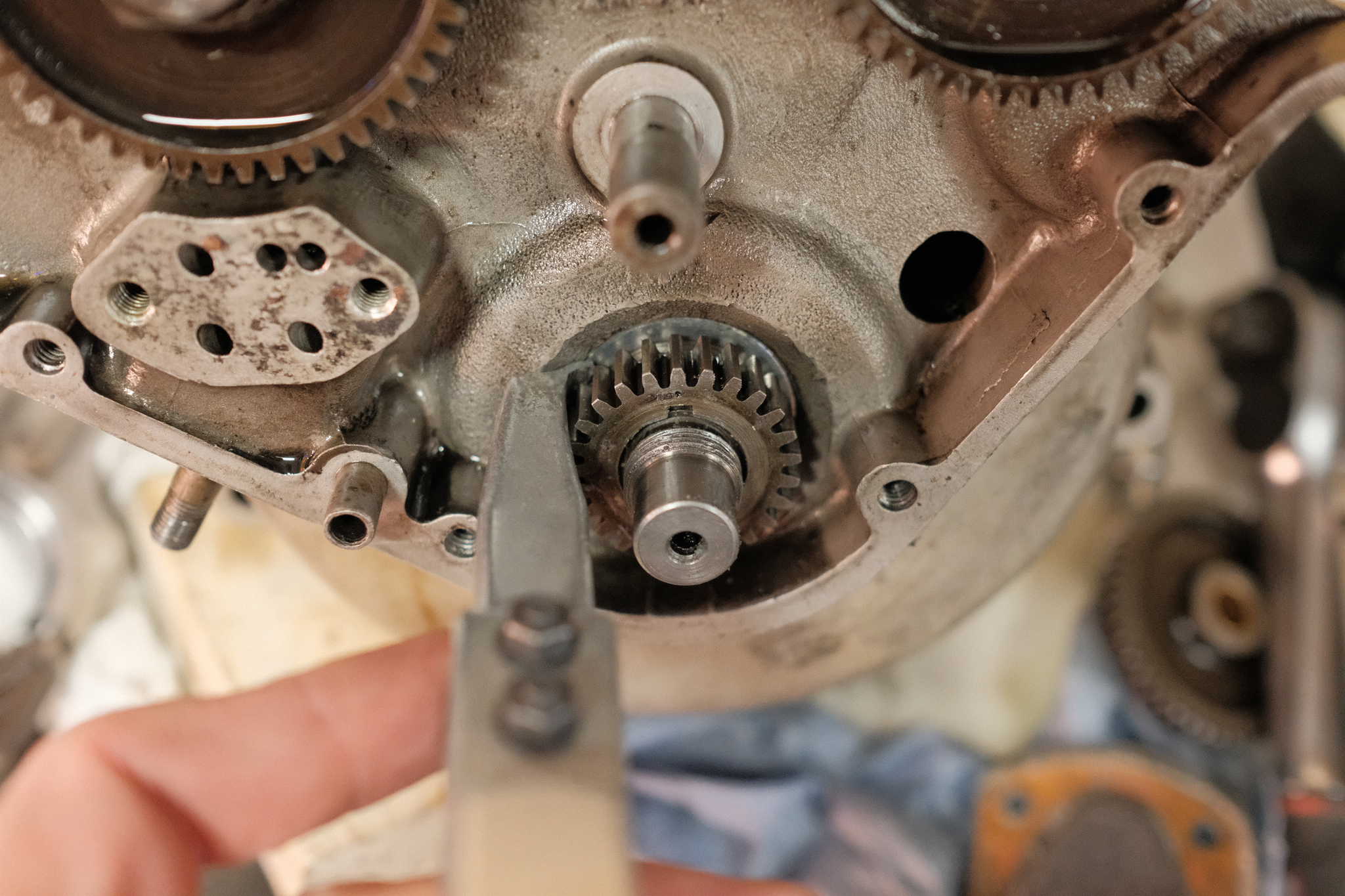

Now as the puller is created in a way to ensure a straight pull away from the surface and the arms cannot be held at an angle when connected, I had to unscrew the arms and then position them behind the pinion gear.

Then I could attach the puller to the arms. Add a vice grip to ensure that they were kept close to the gear and would not slip.

And then it was only a matter of tightening the puller and the pinion gear came right off without any issues at all.

So all in all a great success and even though I used an hour or two on modifying the generic puller, then I saved a good amount of money on an original puller.

Then all I had to do was remove the crankshaft from the engine case and then I would be good to go on cleaning the sludge trap.

Unfortunately I was in for quite a nasty surprise. But that will have to wait for another post.